Sadykhan Premium LLP is engaged in wholesale of pharmaceuticals and medical products. The company has a delivery service in Almaty city, Kazakhstan and the nearby Almaty region cities, such as: Taldykorgan, Chundzha, Kapshagay and Kaskelen. The company faced a number of problems during the delivery of medical goods to Almaty pharmacies. Before to integrate the Relog route planning software, the pharma retailer had eleven intra-city delivery vehicles, and it was planned to hire an additional twelve because the drivers could not cope with the delivery on time. Unscrupulous drivers carried out fraudulent manipulations with fuel, deviated from the route, and went home without permission, reducing their working hours. It was impossible to track it down, the company's money kept slipping through their fingers. In addition, periodically in the spring and autumn, the number of requests from pharmacies increased by an average of 20%. At such moments, fleet dispatchers did not have time to process all orders; they needed a service that would facilitate the registration of requests.

Logistics reanimation

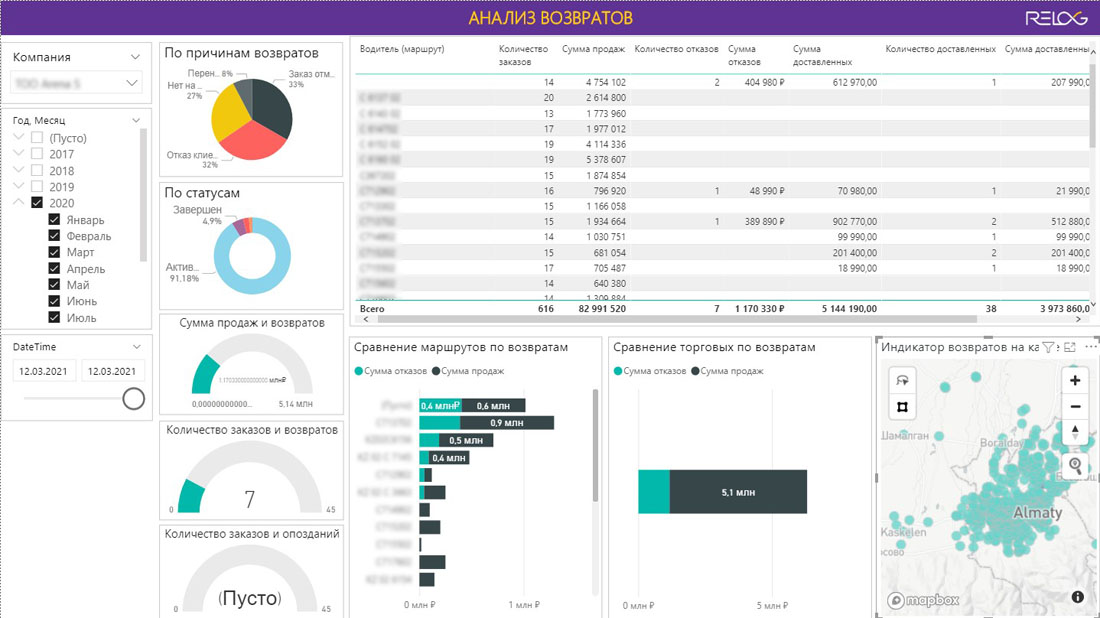

Sadykhan Premium LLP started to integrate the Relog system in their logistics processes in August 2017; by May 2018, the software had already been fully adapted to the pharmacy network needs. Transportation took place in the morning and evening, and initially all eleven drivers returned to the warehouse for a second load. After the system’s integration, it was revealed that seven cars are enough for morning trips, and ten for evening ones. Relog route planning software handles the collection and management of information, freeing managers and drivers for more important work and making operations more effective. In addition, our specialists suggested the company to change some of their business processes with the help of Relog Bi analytics, and to include KPI-based driver salaries. The Relog system handles work such as: tracking vehicles, scheduling work, dispatching vehicles, ensuring driver safety, identifying customers’ satisfaction level. All this data ensures that the driver's performance can be tracked and paid fairly. As a result, compensation for gasoline costs was completely eliminated, salaries began to depend on the number of outlets served, and drivers became interested in serving a larger number of pharmacies. Even taking into account the increase in the salaries of drivers, the company's expenses fell by 22-29%. At the same time, the Relog program identified inefficient drivers who constantly deviated from the route.

In addition, the need for manual data processing has disappeared. Just two years ago, before starting to use the Relog route planning software, fleet managers and drivers had to handle everything by hand and spent five hours a week on preparing reports, now - about an hour. Investigation of requests loss cases has become much easier, earlier it took about two hours to identify the reasons for such an omission, now it takes 20-30 minutes. The inconsistent workflows between dispatchers, drivers and pharmacists have disappeared. With Relog mobile app all field service participants can easily track the movement of orders at any time. The pharmacist doesn’t have to call and specify when the goods will arrive, and the fleet dispatcher doesn’t have to call back the drivers.

“The use of IT technologies in pharmacy processes is one of the ways to develop and increase the profitability of the business for large players in the pharmacy segment of the pharmaceutical market. A pharmacy today is a large and complex mechanism with many different processes, it is a huge system for managing numerous divisions, and the larger the network, the more complex this mechanism is. Each participant has to be a team player therefore all steps must be automated as much as possible. Pharmacies can no longer manage without the use of IT tools in order for normal functioning and development ".

Kairat Aubakirov

Head of Sadykhan Premium LLP

Kazakhstan Pharmaceutical Bulletin No. 14 (590), July 2020

Even during the hype for antiviral drugs (the coronavirus pandemic has undoubtedly affected the company's turnover), Relog helped to build more efficient delivery routes and provide a high level of service.

The phenomenon of street quarters

Another problem faced by the pharmacy network is the incorrect distribution of geofences. In general, the delivery mechanism is as follows. Each driver is responsible for a specific geographic sector, in which a certain number of pharmacies are located. Let's say there are twelve sectors and one driver is assigned to each. For example: in each sector there are one hundred different pharmacies. There are pharmacies that have very high sales and they place orders every day. In some of them, the goods are ordered once a week, and sometimes a month. The illogical distribution of geofences made the load of drivers uneven. Relog Bi analytics identified how many orders are made in each geofence and determined the score for each site. Thus, we managed to find the busiest “street quarters” and redistribute them among the drivers. If the delivery was carried out in the most profitable areas, the drivers were assigned a higher KPI. Our Relog team also recomended the company to calculate the efficiency indicator depending on the geofence area: if the "square" is larger, then the KPI is correspondingly less. Thus, based on the Relog Bi analytics, we made the workload even, and the salary fair.

Coped with the tasks

According to the Deputy Director of Sadykhan Premium LLP, Yelnur Nayermanov, the Relog program coped with tasks such as automation of the logistics department, automation of drivers’ tracking and monitoring, automation of reporting and analytics. With the help of the Relog field service fleet solution, logistics costs were reduced by up to 30%, and the vehicle fleet by 15%. Thus, Relog program freed the business from difficulties, facilitated planning, control and analysis of activities.